- Factory direct sales

- Quality Assurance

- Quick response

- Worry-free service

Impact crusher

If you need help please contact us!

Factory direct sales:Yes

Delivery method:Sea/land

Caractersticas 1. Entrada de alimentacin grande, cmara de trituracin alta, alta dureza del material, tamao de bloque grande y menos polvo de piedra del producto. 2. El espacio entre la placa de contraataque y el martillo se puede ajustar fc

- +8613607653853

- 7*24 hours service hotline

Product Introduction

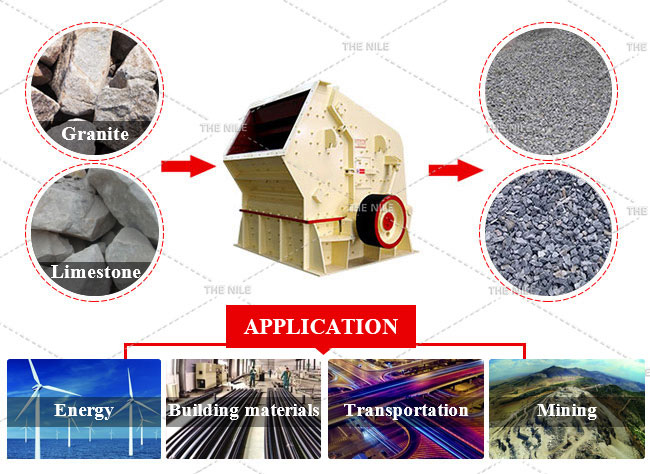

The impact crusher is a new type crusher developed by our company which absorbs the advanced technology at home and abroad and combines the specific conditions of the domestic sand industry and mining industry. It uses the latest manufacturing technology, unique structural design, the finished product is cubic, no tension and cracks, very good granularity, The coarse, medium and fine materials (granite, limestone, concrete, etc.) which can be broken and fed with size not exceeding 500mm and compression strength not exceeding 150MPa.

The impact crusher is widely used in ore crushing, railway, highway and construction industries, for example artificial sand production, because of the djustable discharge size, machine's crushing specifications are diversified.

The impact crusher is widely used in ore crushing, railway, highway and construction industries, for example artificial sand production, because of the djustable discharge size, machine's crushing specifications are diversified.

Working Principle

Impact crusher is a crushing machine which uses the impact energy to break the material. When working, the rotor rotates at high speed driven by the motor, and when the material enters the crushing cavities, it will be broken into pieces with the plate hammer on the rotor and thrown on the impact liner to break again. Then materials bounce back from the impact liner to the plate hammer action area to be broken again. The process is repeated, material is broken repeatedly from large to small into one, two amd three crushing cavities, until the material is broken to the required particle size and discharged from the outlet. Adjusting the clearance between the impact frame and the rotor can change the size and shape of the material.

Impact crusher is a crushing machine which uses the impact energy to break the material. When working, the rotor rotates at high speed driven by the motor, and when the material enters the crushing cavities, it will be broken into pieces with the plate hammer on the rotor and thrown on the impact liner to break again. Then materials bounce back from the impact liner to the plate hammer action area to be broken again. The process is repeated, material is broken repeatedly from large to small into one, two amd three crushing cavities, until the material is broken to the required particle size and discharged from the outlet. Adjusting the clearance between the impact frame and the rotor can change the size and shape of the material.

Technical Data of the Impact crusher

| Model | Specification (mm) | Feeding Opening Size (mm) | Max Feeding Size (mm) | Capacity (t/h) | Power (kw) | Hammer (qnty) | Dimension (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 250 | 20-70 | 37-55 | 9 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 300 | 50-90 | 55-75 | 15 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 300 | 70-130 | 110 | 17 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 300 | 100-180 | 132 | 22 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 350 | 130-250 | 200 | 26 | 3180×2720×2620 |

| PF-1320 | Φ1320×2000 | 860×2030 | 400 | 300-350 | 315 | 30 | 3218×3320×2620 |