- Factory direct sales

- Quality Assurance

- Quick response

- Worry-free service

Ultrafine Mill

If you need help please contact us!

Factory direct sales:Yes

Delivery method:Sea/land

Main Application HGM100 Ultrafine mill is a machine for producing fineness and ultra-powder .It mainly is suitable for, the low degree of hardness, the mohs scale is not bigger than 7 level non-flammable explosive brittle material, like cal

- +8613607653853

- 7*24 hours service hotline

Main Application

HGM100 Ultrafine mill is a machine for producing fineness and ultra-powder .It mainly is suitable for, the low degree of hardness, the mohs' scale is not bigger than 7 level non-flammable explosive brittle material, like calcite, chalk, limestone, dolomite, kleit, bentonite, talc, mica, magnesite, illite, leaf agalmatolite, vermiculite, sepiolite, concave-convex good stone, rectorite, diatomaceous earth, barite, gypsum, alunite, graphite, fluorspar, rock phosphate, potassium ore, pumice and so on 100 many kinds of materials.

Main structure & Working principle

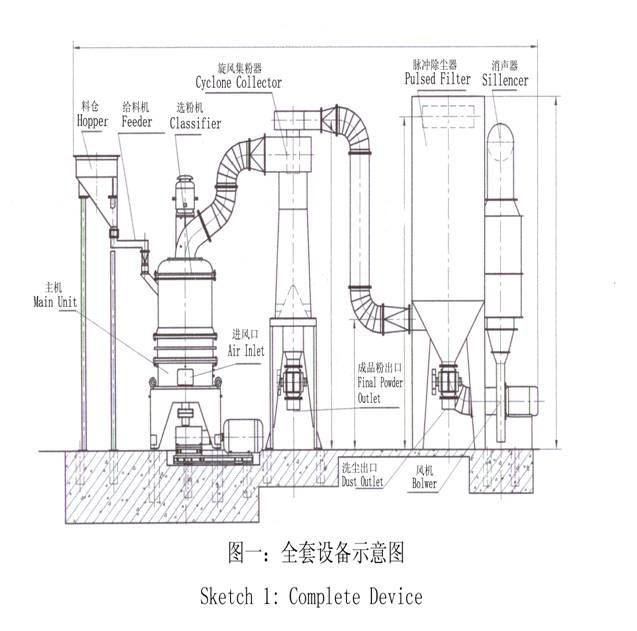

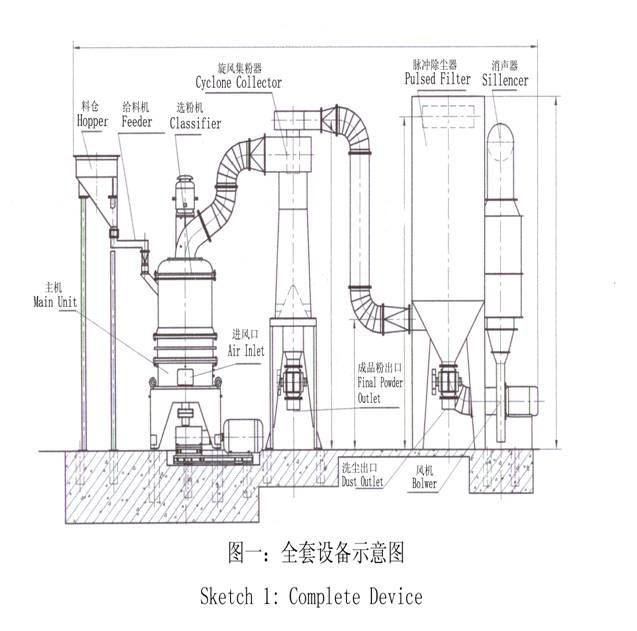

Whole structure of HGM100 Ultrafine Mill(see figure 1): hammer crusher, bucket conveyer, hopper, spiral feeder, main unit, frequency conversion classifier, isolation booth、 cyclone collector device, impulse dust cleaner. It can be equipped automatically according to different requirement, such as the jaw crushing system (JAW crusher).

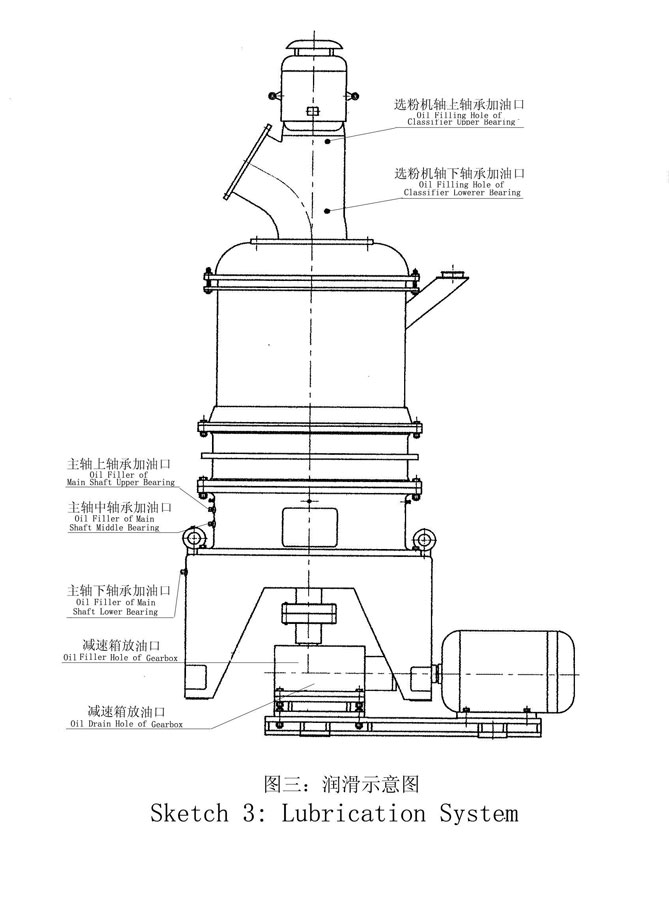

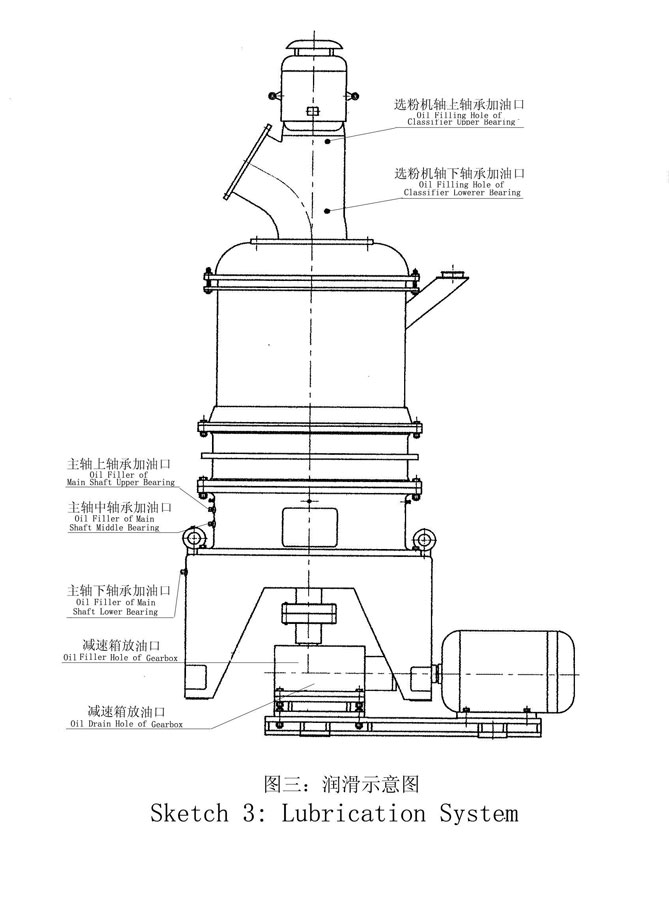

The main unit consists of decelerator, crushing system, classifier system (see figure 2)

When work, the bulk material becomes the finely ground particles after the hammer type breaker to send in the Chu bunker stave by the elevator, again passes through the spiral feeding engine and the inclined inlet pipe, delivers evenly the material the turntable middle, the main engine electric motor through the reduction gear impetus main axle and turntable revolving, the turntable edge roller sells leads several dozens link rollers in to rub in the link roller conveyer to roll and to revolve.

The material disperses under the centrifugal force function to the circumference nearby, and falls rubs the link in the roller conveyer to surround the roller ramming, rolls the milling, the attrition crushes, the material falls after the first smashing second and third, through the high-pressured gentrifugalism air blower pavement pumping the surrounding air inspiration within the aircraft, after and will pass through the third smashing the material to lead elects the powder within the aircraft.

Chooses the powder machine internal rotation the worm gear to cause the thick material to recede the grind, the fine dust enters the tornado collection dusting equipment and along with the air current discharges by its lower part discharge valve is the end product, but has the few thin dust air current then purifies after the pulse dust remover discharges through the air blower and the silencer.

Wearing parts list

In order to make the buyer using the equipment conveniently, we enclose the mainframe wearing parts as below for your reference. Please refer the description for other wearing parts.

HGM100 Ultrafine mill is a machine for producing fineness and ultra-powder .It mainly is suitable for, the low degree of hardness, the mohs' scale is not bigger than 7 level non-flammable explosive brittle material, like calcite, chalk, limestone, dolomite, kleit, bentonite, talc, mica, magnesite, illite, leaf agalmatolite, vermiculite, sepiolite, concave-convex good stone, rectorite, diatomaceous earth, barite, gypsum, alunite, graphite, fluorspar, rock phosphate, potassium ore, pumice and so on 100 many kinds of materials.

Main structure & Working principle

Whole structure of HGM100 Ultrafine Mill(see figure 1): hammer crusher, bucket conveyer, hopper, spiral feeder, main unit, frequency conversion classifier, isolation booth、 cyclone collector device, impulse dust cleaner. It can be equipped automatically according to different requirement, such as the jaw crushing system (JAW crusher).

The main unit consists of decelerator, crushing system, classifier system (see figure 2)

When work, the bulk material becomes the finely ground particles after the hammer type breaker to send in the Chu bunker stave by the elevator, again passes through the spiral feeding engine and the inclined inlet pipe, delivers evenly the material the turntable middle, the main engine electric motor through the reduction gear impetus main axle and turntable revolving, the turntable edge roller sells leads several dozens link rollers in to rub in the link roller conveyer to roll and to revolve.

The material disperses under the centrifugal force function to the circumference nearby, and falls rubs the link in the roller conveyer to surround the roller ramming, rolls the milling, the attrition crushes, the material falls after the first smashing second and third, through the high-pressured gentrifugalism air blower pavement pumping the surrounding air inspiration within the aircraft, after and will pass through the third smashing the material to lead elects the powder within the aircraft.

Chooses the powder machine internal rotation the worm gear to cause the thick material to recede the grind, the fine dust enters the tornado collection dusting equipment and along with the air current discharges by its lower part discharge valve is the end product, but has the few thin dust air current then purifies after the pulse dust remover discharges through the air blower and the silencer.

Wearing parts list

In order to make the buyer using the equipment conveniently, we enclose the mainframe wearing parts as below for your reference. Please refer the description for other wearing parts.

Non-Standard wearing parts

| No. | Item | QTY | Material | Installationsite |

| 1 | Roller | 21 |

Wear-resisting Alloy Steel |

interlayer of the turntable |

| 2 | grinding ring | 1 |

Wear-resisting Alloy Steel |

inner layer of the main unit center |

| 3 | Shaft pin | 7 |

Wear-resisting Alloy Steel |

Turntable circle |

| 4 |

Upper dispersing materials plate |

1 | Cast steel | Above the turntable |

| 5 | Turntable | 1 | Cast steel | Inside of the mill chamber |

| 6 | Cap nut | 1 | Cast steel | spindle nose |

| 7 | Coupled axle-pin | 10 | PA | |

| 8 | Sealing ring | 2 | PTFE |

Underneath of the powder concentrator |

Technical Data of the Ultrafine Mill

| Name |

Unit

|

Parameter | ||

| HGM80 | HGM100 | HGM125 | ||

| Number of grinding rollers | Unit | 21 | 27 | 40-44 |

| Number of grinding rings |

Sleeve

|

3 | 3 | 4 |

| Average working diameter | mm | 800 | 1035 | 1300 |

|

Feed granularity

|

mm | ≤10 | ≤10 | ≤20 |

|

Fineness of finished product

|

μ m / order

|

47-5/325-2500 | 47-5/325-2500 | 47-5/325-2500 |

| Yield | Kg/h | 4000-600 | 6000-900 | 8000-1200 |

|

Shape dimension.

(long x width x height) |

m | 11.9×2.7x5.8 | 14.5x3.8x6.3 | 14x9x10.25 |